GroupeSTAHL History

Faster, Easier, Better

One of our core values at GroupeSTAHL is to make it easier for customers of all sizes to print the custom garments they need. Any quantity, any fabric, any finish. Since 1932, we have been introducing heat printing products and services that provide the quality results you demand while increasing production efficiencies.

1932: World’s 1st Die-Cut Lettering

With the demand for names and numbers on sports jerseys beginning to grow, A.C. Stahl made it easier for decorators to “do-it-yourself” by offering popular die-cut styles, eliminating the need for hand-cutting and improving productivity.

1951: Plasti-Bak™ 1st Thermo-Plastic Adhesive

This adhesive, which was sold separately and as a backing to our PolyTwill, Felt and other materials, allowed decorators to seal letters to garments before sewing. Introduced by Ernie Stahl and one of the best innovations of the decade, Plasti-BAK™ was considered a huge time-saver by our customers.

1952: Boxed Letter Assortments

Stahls’ was the only company in the industry selling individual letters and was also the first to sell lettering in boxed assortments. Stahls’ Lettering Kits are still regularly stocked in stores around the world.

1977: Thermo-FILM® For Team Printing

This breakthrough, patented combination of a polyester adhesive topped with flexible polyurethane changed the world of athletic printing for the better. A lightweight, durable alternative to PVC (vinyl) Thermo-FILM is the first “green” lettering and numbering material and is still the top-selling material choice for numbers and by the roll for CAD-CUT®. It applies in seconds, is known to outlast the garment and has superior opacity and dye-migration blocking capabilities.

1977: Rotary Press Manufactured Letter Perfect Strips

Stahls’ ability to mass produce high quality letters and numbers using a rotary press not only revolutionized the business but also made lettering more affordable than ever for our customers. This decade saw the first explosion of the t-shirt market and personalization popularity. Stahls’ was no longer alone in the market. With dozens of competitors, a “Switch to Stahls” campaign was a marketing winner since Stahls’ was the manufacturer with the best quality and the lowest costs.

1984: First Water Jet

Credit as the inventor of Water-Jet custom cutting technology belongs to Craig Stahl. A pioneer in the field of custom lettering and logo cutting, he was the first to successfully cut twill and other materials using a computerized, water-driven cutter. And this during a time when high-speed computers and highly complex graphic design programs didn’t exist. It was a breakthrough technological achievement; one that helped put Stahls’ on the map as a supplier of custom cutting services. Craig also designed cutter-compatible script fonts, some of which are still in use at Stahls’ today.

1986: Custom Logo Services and MLB Licensing

Thanks to the ability to efficiently cut Poly-TWILL™, Thermo-FILM®, Thermo-FLOCK® and more, Stahls’ begins offering a wider selection of custom logo cutting services, including many variations of Athletic Script with Tails.

1986: Hotronix® Heat Press–So Advanced It’s Simple

With a technology team led by industry heat press guru Ron Anderson, Stahls’ investment in re-inventing and engineering a new generation of heat presses was unprecedented. The result was the Hotronix Swinger–the first press in the world to eliminate cold spots, control time, temperature and pressure with digital precision and offer programmability. Manufactured in Masontown, Pennsylvania, the Hotronix name remains synonymous with heat printing innovation and precision and Stahls’ Hotronix has grown to become the world’s largest manufacturer of heat presses.

1988: Stahls’ Invents CAD-CUT® Technology

The term CAD-CUT, which is commonly used in the garment decoration industry to refer to the practice of using a vinyl cutter to create garment graphics, is a registered trademark of GroupeSTAHL. Stahls’ was the first company in the world to take the concept of cutting your own graphics mainstream. As the leader in athletic number for decades, Stahls’ saw the potential advantage of allowing their customers to custom-cut heat transfer materials on demand. Having been on the forefront of development of heat-transfer materials for die-cutting, Stahls’ set out to make cuttable materials available in roll format. Today Stahls’ manufactures an extensive line of patented CAD-CUT materials, which is continually innovated to keep up with the changing needs of the imprinted sportswear industry.

1997: Licensed Supplier to NHL®

Stahls’ introduces Official NHL®/NHLPA® Player Name and Number Kits, which allow decorators to offer the service of Replica Jerseys when applied to official NHL jerseys. Buyers receive a name, number, sleeve number and official NHL® hang tag to apply to the finished jersey. Stahls’ also partners with the NHL® to provide on-site heat printing services at the NHL® All Star Games and other events.

1998: Licensed Supplier to NBA®

This is the first year that Stahls’ supplies the official NBA® store in NYC. Over the years, Stahls’ relationship with the NBA has grown and we also provide online order fulfillment for many official stadium stores as well as on-site decorating services at All Star Games.

1998: CAD-COLOR® Advantage™

The introduction of CAD-COLOR Advantage media makes heat printing the most cost effective way to print full color logos on any fabric, including nylon. Designed for use with eco-solvent Printer/Cutter technology. CAD-COLOR Advantage is a breakthrough material that makes full color logo printing more affordable and more accessible.

2002: Licensed Supplier to NFL®

Thermo-FILM® is tough enough for the NFL®. Known for immediate turnaround on custom orders and internet order fulfillment capabilities, our Decorating Fulfillment Center in Masontown, Pennsylvania is contracted by the NFL to supply Bulk Roster Names for Players as well as online order fulfillment for end consumers.

2005: Player Perfect® Pre-Spaced Team Names

This time-saving custom cutting/printing service allows customers to order one-step graphics that include a player’s name and number on one sheet.

2007: Hotronix® 1st Auto-Opening Manual Clam Press

Hotronix Auto Clam debuts with patented magnetic release. Using electronic magnetic technology, this manual heat press automatically opens at the end of its pressing cycle. This revolutionary improvement, formerly available only on semi or fully automatic heat presses that require a compressor, made it possible for an operator to start a press and walk away to do other tasks without fear of ruining a shirt.

2007: Hotronix® Perfect Pressure®

A digital pressure display on Hotronix heat presses allows the operator to set the heat press for the exact amount of pressure needed to correctly print a heat-applied graphic. This eliminates the need to use guesswork or experimentation to find the right pressure.

2008: CAD-PRINTZ® Digital Transfers

The barrier to full color is broken with CAD-PRINTZ Digital Transfers. Now anyone can order highly detailed, full color transfers for heat application on any fabric or item with our CAD-PRINTZ transfer service. Upload artwork or choose from template-based full color designs at Transfer Express.

2010: Stahls’ CAD-CUT® Direct

Introduces the first lab certified materials for safety, durability, and performance.

2010: Hotronix® Fusion Heat Press

First patented dual swing or draw function providing “threadability.”

2012: Behind the Scenes at the NFL® Draft

Our heat printing experts print custom NFL jerseys for new draft picks in less than 90 seconds and present the jerseys to the Commissioner to give the players, live on stage.

2012: Hotronix® Air Fusion®

Hands-free operation with 120 PSI and auto-opening capabilities make the Air Fusion one of the most requested heat presses of all time. Expectations are exceeded and it becomes best-selling automatic press.

2012: Hotronix® Heat Press Caddie

This handy stand allows existing Hotronix Clam press owners to convert their press to offer time-saving “threadbility.”

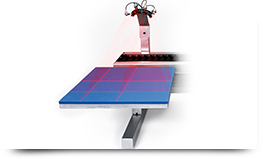

2014: Hotronix® Dual Air Fusion

High-volume operators can now increase production output as the upper platen moves between two heat printing stations, featuring laser guided production and dual platen programming capabilities.

2014: STiX² Adhesive and SuperTEK™ Line of

CAD-COLOR® Media

Universal heat transfer films that have the ability to stick to anything-from leather to performance wear, have extreme stretch, have low temperature application, and have sub-block properties

2014: 28 New Pre-Cut Number Styles

More choices for team numbering with updated styles. Still the fastest, easiest way to number individual jerseys.

2015: Hotronix Laser Alignment System

Improve production quality and speed with four lasers that show exactly where the logo or design needs to be placed. Perfect placement every time.

1930s

1932: World’s 1st Die-Cut Lettering

With the demand for names and numbers on sports jerseys beginning to grow, A.C. Stahl made it easier for decorators to “do-it-yourself” by offering popular die-cut styles, eliminating the need for hand-cutting and improving productivity.